wristed arm welding?

wristed arm welding?

ok I used the search function but I didn't find what I needed.........what rod would y'all use to weld up a wristed arm?

I know you don't need nickel, but what did everyone use?

I know you don't need nickel, but what did everyone use?

71 Bronco - twin sticked, full width, 2" lift, wristed arm, lots of rust...

http://www.catalystcycles.com

http://www.catalystcycles.com

so your getting ready for the wristed arm.....  . why not niclke? i dont know much about arc welding, and sizes of rod. the guy who did my arm used nickle he said it has less impurities.

. why not niclke? i dont know much about arc welding, and sizes of rod. the guy who did my arm used nickle he said it has less impurities.

he also told me something about some kind of weld filler that you could use a torch to lay out. he told me it would make the filling of the arm quicker. dont know how good it work's though might try it if i build another.

he also told me something about some kind of weld filler that you could use a torch to lay out. he told me it would make the filling of the arm quicker. dont know how good it work's though might try it if i build another.

Darker than your average wheeler!!!!

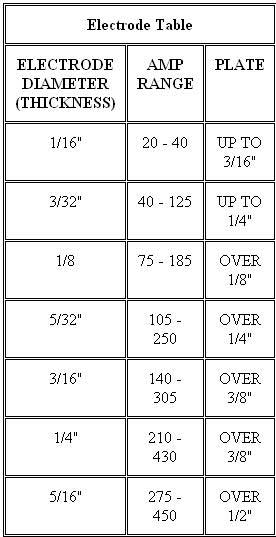

I had some 7018's and 6013's laying around but I wasn't sure how well they would work. the 7018's splater less but they both look a little small. I figured 150 amps would be a good place to start for a nice penitration, I guess I could just keep filling with the 7018's.......thanks!

I should get my stock arms back on friday. and I get paid on wed so I will hit the metal store and probably start on thurs. I have thought about reinforcing the whole arm, filling in the whole grove on both sides. they had a good tread on FSB about how to mak a beefed up extended arm I was watching a few weeks ago. I will let y'all know what I come up with.

I should get my stock arms back on friday. and I get paid on wed so I will hit the metal store and probably start on thurs. I have thought about reinforcing the whole arm, filling in the whole grove on both sides. they had a good tread on FSB about how to mak a beefed up extended arm I was watching a few weeks ago. I will let y'all know what I come up with.

71 Bronco - twin sticked, full width, 2" lift, wristed arm, lots of rust...

http://www.catalystcycles.com

http://www.catalystcycles.com

I think they might have been squattyd's, they looked nice.

I am in the same boat.....I grabbed the set when I got that 68 D44 housing, so I plan on wristing them and swpping out one when I put in my coils so I have a spare set. thought about selling one after I wrist it to make some money back for the rig.I think im going to get another set of arms to use to wrist one and then have a spare...

71 Bronco - twin sticked, full width, 2" lift, wristed arm, lots of rust...

http://www.catalystcycles.com

http://www.catalystcycles.com

71 Bronco - twin sticked, full width, 2" lift, wristed arm, lots of rust...

http://www.catalystcycles.com

http://www.catalystcycles.com

Well I didnt get the extra set of arms. The guy I got a TON of stuff (from for nothing) I didnt feel good about asking for them. I will get one or more the next time I goto the junk yard to mess around with. I think I have found that with 7014 1/8" rod and my buzzbox set at 130amps is perfect for penetration and a good looking weld. This took me forever to try this all out....

You guys should step up to a little bigger rod. I think I use 3/16 7014 for most stuff. With 7014, you want to make sure everything is clean. 6011 is better at cutting through gunk.

7014 doesn't penetrate very well compared to the 60 series rods, so prep work is very important.

FYI: to decode the welding rod numbers, on a 7014

The 70 is the tensile strength of the rod.

The 1 is the position the rod can be used in

1 - any position

2 - overhead and flat

3 - flat only

The 4 is the type of rod, and if it's AC, DC or both.

7014 doesn't penetrate very well compared to the 60 series rods, so prep work is very important.

FYI: to decode the welding rod numbers, on a 7014

The 70 is the tensile strength of the rod.

The 1 is the position the rod can be used in

1 - any position

2 - overhead and flat

3 - flat only

The 4 is the type of rod, and if it's AC, DC or both.

Last edited by Nobody on Mon Nov 15, 2004 8:00 am, edited 1 time in total.

I have an entire book on methods and materials from a class I took a few semesters ago, and a photocopied packet with all the info on it. I will see if I can find it in the large stack of junk I have on the book shelf if y'all want some more info. or if matt wants to post it for refference?

71 Bronco - twin sticked, full width, 2" lift, wristed arm, lots of rust...

http://www.catalystcycles.com

http://www.catalystcycles.com