He doesn't know where I live. so I am not worried much about that.

The first order of business was to do some diagnostic and see what this thing's ailment really was. I had been told that it had a blown head gasket, but without some sort of troubleshooting, I wasn't about to go digging into the motor. First, I used a block tester to look for exhaust in the radiator. nothing. Second, I looked for water in the oil. None visible. Third, I looked at how much water was coming out of the exhaust pipe when it was running... Negligible amounts. Fourth, I disconnected the coil and spun the engine over... bingo! I could hear that not all cylinders had the same compression. Granted, that doesn't necessarily mean a blown head gasket, but I was going to have to rip it down anyway to see what it was. I decided to treat it like a blown HG and started tearing it down. Here is where we started:

I started by getting the A/C compressor out of the way. you can disconnect the brackets and compressor and move it out of the way without breaking the seals. I don't know if the A/C works in this truck, so I left it all intact... Just in case. The compressor easily swings out of the way and lays neatly on top of the battery. you can move it back to the stock location when you are done and want to close the hood. you could also take the battery out and lay it in the battery tray.

I went to work disconnecting the throttle linkage, Air box, lines, EGR valve and several electrical connectors. A word of advice on this; keep a roll of masking tape and a Sharpie handy so you can mark your connections. Also, take pictures in case you need a visual aid to get it all back together. you can't remember where everything goes unless you have done this several times before. Believe me, you don't want to create a puzzle for yourself to figure out later.

I tried to clean the engine so that it wouldn't be a nasty job, but that was an epic fail. there was just too much grease and crud on the engine. I took out the radiator and fan shroud. They were sort of in the way, and I have to replace the water pump anyway, so... Next was to remove the upper intake. There are vacuum lines, electrical connectors and a ground on the back near the firewall. there are looms of cables woven in between the legs of the upper intake. All of these should be marked so you know how they go back together later.

I got the radiator, shroud and upper intake out and set them in the building. Next, I had to remove the fuel lines from the fuel rail. There is a tool for that and you don't want to mess with it without the tool. Given some persuasion, you probably can get the lines off without it, but you risk damaging the fittings... Besides, at about $5.00, the tool is cheap enough.

Once the fuel lines are off, you can tuck them away into a place in the core support to keep dirt from entering the lines. There are a combination of studs and bolts that hold the UI in place. Remove them and you should be able to lift the upper intake out. Go slowly to make sure that you have disconnected the vacuum lines and electrical connections. I removed the ground strap from the rear of the UI once I had it free from the engine. Here is a shot of the engine with the UI and one valve cover removed:

Then, I moved to the distributor. I took the cap off and marked where the rotor button was on the lower casing of the distributor. I also marked the distributor in relation to how it was sitting in the truck so that I will be able to put it back in the same position during reassembly. As you pull straight up on the distributor, the rotor button will start to turn counter-clockwise. I marked the distributor casing again once the gear was free of the cam to assist in re-installation later. I discarded the cap and wires. The rotor is still installed in the distributor, but will get replaced later when the distributor is seated back in properly.

Once the lower intake came off, I removed the valve covers, then the rocker arm assembly. There are 3 bolts that hold the rocker assembly down to the head. Loosen the one in the center first, followed by the other two in either order. The rockers lift off easily after removing the bolts. They are identical, but you want to make sure they go back on the same side they came off of. I labeled mine with my trusty tape and a sharpie. I got a box and cut slits in it so I could keep those bolts and the push rods in order. If you are going to re-use the push rods, you want them to go back in the same places they came out of. Take caution not to mix them up.

Once taking the intake gasket off, I did an inspection of the lifter valley, particularly to see if the oil journals were draining properly. As expected, about half of the return journals were gunked over. I will address this later. I am a bit torn between cleaning them out with a wire coat hanger or taking a small auger bit for a drill and running that down to lift the crud out of the journals. Of course, I will have to use extreme caution not to run the bit into the metal and scar it up. I will follow that up with some solvent and some sort of heavy-duty pipe cleaner to make sure they are clear.

I decided to take my exhaust manifolds off at the flange and remove them as a single unit with the heads. I had to break out the big impact wrench and use a LOT of penetrating oil and a breaker bar to get the bolts out. That was probably the most painful part of this build so far. I had a bit of trouble with the left side head removal doing it this way because the EGR tube got wedged into the oil dipstick tube. It took a fair amount of finesse to get it out. This of course after taking the head bolts out. those were in there really tight and I had to use a breaker bar on a couple of them. Be careful, though as these bolts have Torx heads and if you strip the bolt head out it will be a bastard to get out. My Torx bit twisted a little taking the head bolts out, so I will have to buy another one for reassembly to make sure I don't damage the bolts.

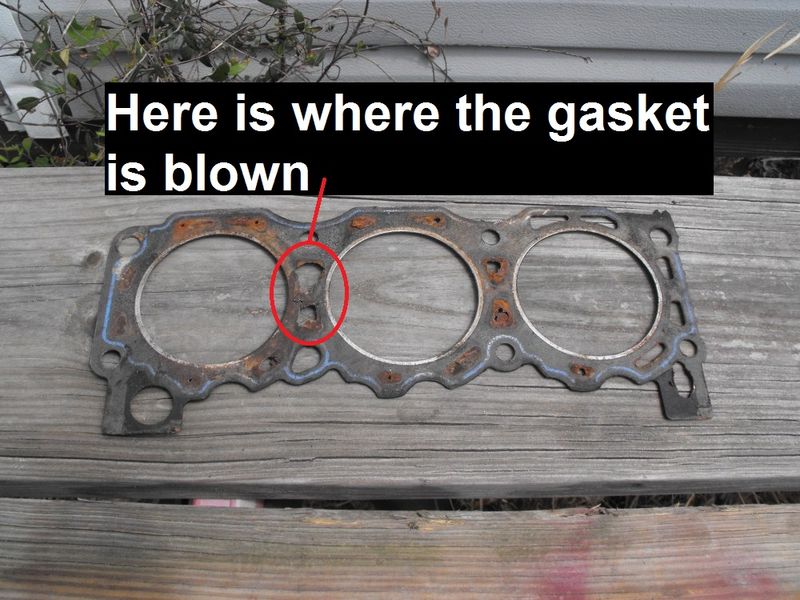

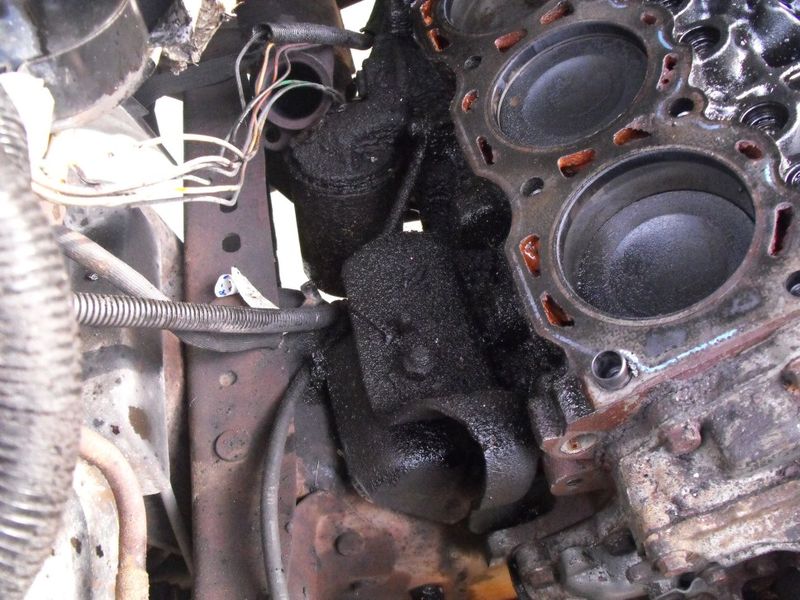

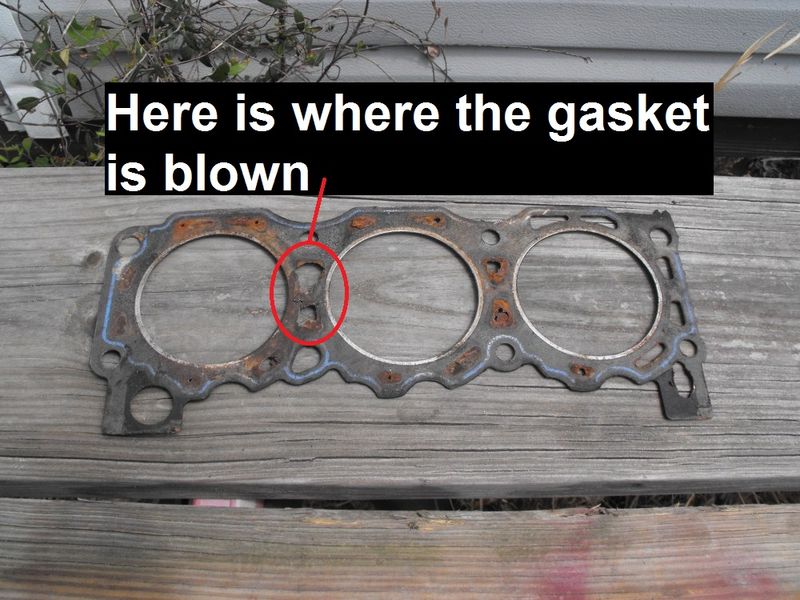

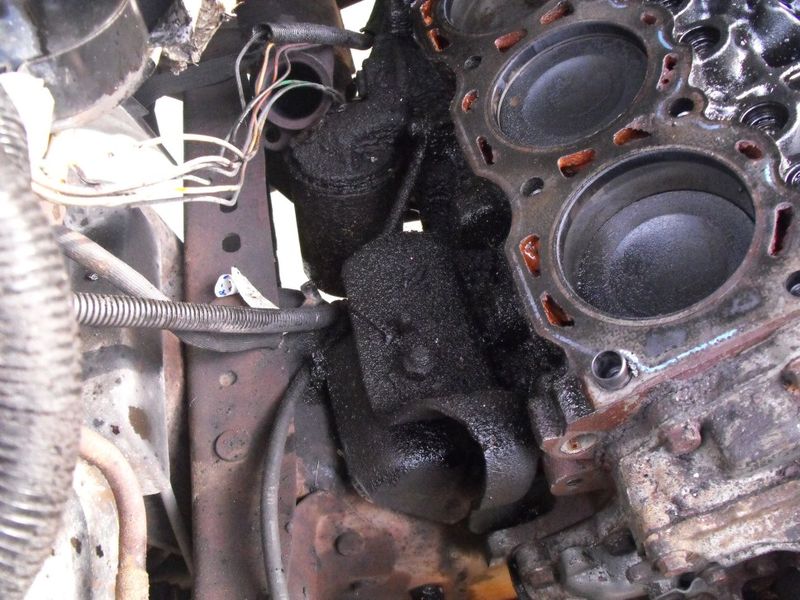

Once I had the heads off, I did a basic visual inspection - Starting with the gaskets to look for signs of where the failure was. I found it pretty quickly on the left head between the water jackets between the #1 and #2 cylinders. I inspected the head in the same area as the gasket failure and discovered a crack between the water jackets. That was enough for me to decide to go with a pair of re-manned heads. Upon inspection of the gaskets and heads. I found gobs of stop leak/Block sealer that had almost completely blocked off the cooling passages between the block, heads and intake. If the engine is the heart of the truck and the water is the blood, it basically had a heart attack. Here are some pics of the gaskets and blockages:

Since I was told that the B2 also had a leaking water pump and that the heater core had recently been replaced, I suspect that the previous owner tried to fix the water pump by dumping a bunch of stop leak into the radiator. I am fairly certain that this was the cause of the blown gasket/cracked head. Incidentally, the water pump was not leaking... The heater hose had a hole in it and sprayed water down the front of the pump. I am replacing the pump anyway. They are cheap enough.

Here are a few shots of the work in progress:

So, while the heads are off and I am waiting on replacements, it is cleaning time. Since I had all of the parts off, I thought I would take the opportunity to not only clean the parts that came off, but paint them up so the engine will look good once it goes back together.

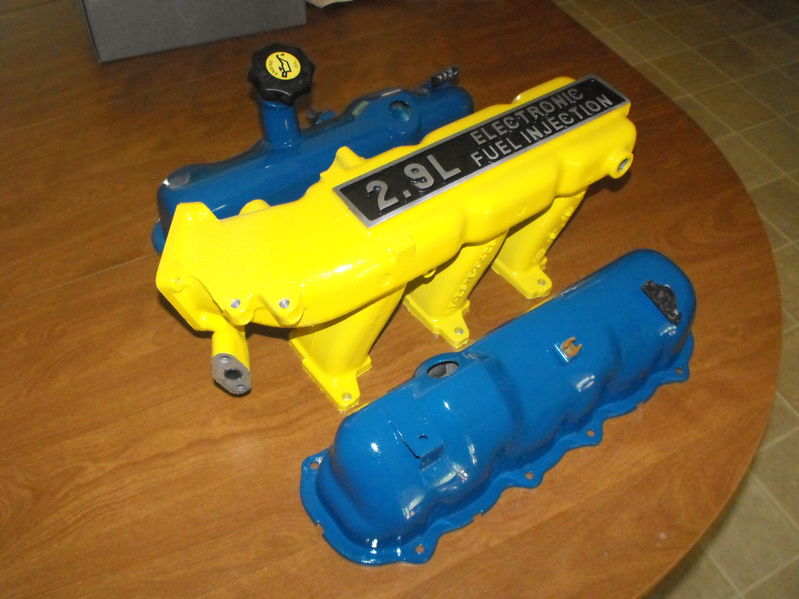

I started with the valve covers. 3 cans of easy off on both the inside and the outside cleaned them up really well. The original color of the covers was battleship Grey, but I wanted to go with something a little more colorful, so I painted them blue. I know, I know... Blue has been done to death, but I think it will look great next to other plans I have for other parts.

The insides of the covers was NASTY! There was a bit of sludge and more of my favorite... Baked on CRUD. Easy-Off to the rescue again! I scuffed, primed and shot the covers with 4 coats of blue and 4 coats of clear. After letting them dry for 12 hours, I baked them in the oven at 200 deg. for an hour. They came out really nice.

From the look of the throat of the throttle body, I decided that the inside of the upper intake must be nasty as well, and I was right. They were not only blackened, but there was crud buildup in there as well. Again, the Easy-Off came out. I removed all of the sensors from the intake to make sure I didn't damage them and put them into a 1 gallon zipper bag. I like the zipper bags that have the write-on area so I can label what the parts are that are inside. I filled the intake with the oven cleaner and let it soak in it for about an hour. I dumped it, rinsed it and repeated the steps until I could get no more out and the rinse water was running clear.

After cleaning and scouring, I cleaned and taped off all of the mating surfaces so I wouldn't get any paint on them. I also filled the threaded holes with cone-shaped wads of masking taps so that I wouldn't paint the threads. Now for the colors... I settled on Black, Yellow and Silver for the colors on the upper Intake. It is aluminum and has raised lettering on the top; I taped off the raised border around the lettering and painted the lettering and background black. Once that was dry, I taped that area off and painted the rest of the upper intake yellow. After the paint was dry, I removed the tape and sanded the raised letters to get the black paint off of them, revealing the silver/aluminum color underneath. I cleaned it up with prep solvent and blew it dry with the air compressor and then put 4 coats of clear over it. The next day, I baked it in the oven at 200 deg. for an hour.

here they are before and after...

Before:

After:

I will update as the build goes on.

Tom